Imagine this: a delivery truck's backing into the bay, your team's ready, and suddenly, the overhead door jams. Now everything's stalled, productivity dips, and deliveries are delayed. All because of one worn part that could've been caught with routine maintenance.

When it comes to facility operations, your loading docks and overhead doors are the unsung heroes of your workflow. They're the first point of contact for incoming deliveries and the last checkpoint before products head out the door. But like any high-use asset, they don't stay reliable forever, not without regular maintenance.

Why Dock & Door Maintenance Should Be a Priority

Think of your loading dock and door systems like the suspension on a work truck: they take a beating, day in and day out. Every bump, misalignment, or worn part adds up over time, and when failure hits, it doesn't just slow you down. It can bring operations to a complete stop, risk employee injury, or result in damaged goods.

According to industry data, up to 70% of dock-related delays stem from preventable equipment failures.

Preventive maintenance keeps these systems operating smoothly, safely, and in compliance with OSHA standards. It's not just about avoiding downtime, it's about protecting your team, your shipments, and your bottom line.

What Regular Maintenance Includes

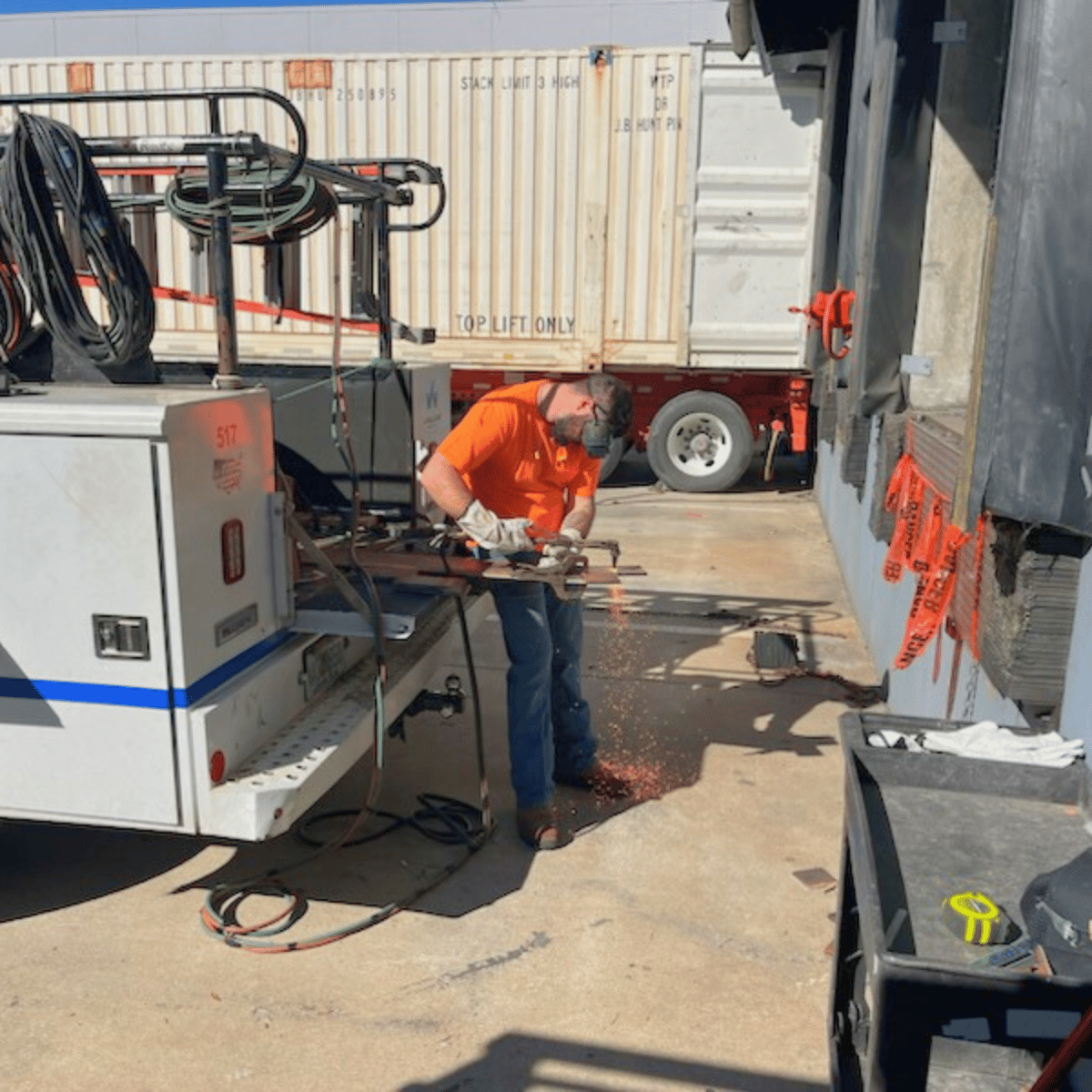

At J. Williams Industrial Group, our Dock & Door Maintenance services cover:

Dock Leveler Inspections & Repairs - We check for hydraulic leaks, spring fatigue, and alignment issues that affect performance and safety.

Overhead & Roll-Up Door Maintenance - From worn rollers and bent tracks to faulty sensors, we handle it all to keep doors operating without a hitch.

Seal & Shelter Repairs - Protect your climate control and keep pests and contaminants out by maintaining tight, secure dock seals.

Preventive Lubrication & Adjustments - Small tweaks go a long way. We fine-tune your equipment to reduce stress on moving parts and extend life cycles.

How Often Should Maintenance Be Scheduled?

That depends on usage. For high-traffic docks, quarterly inspections are a smart choice. Lighter-use areas might be fine with biannual visits, but skipping service altogether is a gamble. We work with you to build a maintenance schedule that fits your facility's traffic, budget, and equipment profile.

Don't Wait for Downtime

Unplanned outages cost more than just repair fees. They affect delivery timelines, productivity, and employee safety. By scheduling routine maintenance, you reduce the risk of costly breakdowns and gain peace of mind that your operation will keep moving.

Let's Get You on a Plan That Works

Unplanned breakdowns cost more than just repair fees. They disrupt workflows, delay shipments, and impact safety. Stay ahead of failure with a proactive plan that works for your facility.

Ready to schedule an inspection or set up a custom maintenance program?

Contact the team at J. Williams Industrial Group and keep your operations moving.